- : 0086-21-61182423

- : 0086-21-61182425

- : [email protected]

- : Room 301,Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Improper welding of X80 pipeline may cause cracks

- Brief introduction of API X52 pipeline steel

- The difference between PSL1 and PSL2

- Harm of inclusions in X70 pipeline steel

- API 5L pipeline pipe

- X52 steel plate surface quality standards that need to be met

- The basic production process of API 5L X60 pipeline steel

- The key to Q460D steel welding process

- What does the heat treatment of Q690 Steel include?

- Reasons for choosing Q690D steel

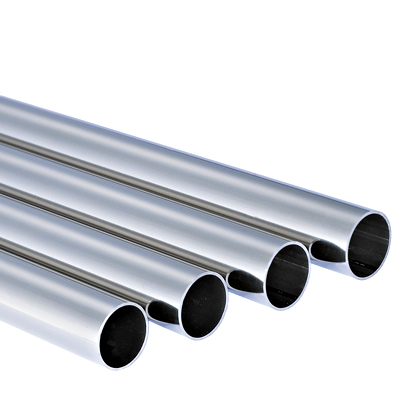

Duplex stainless steel 2507(S31750) price

katalor Stainless inventory now includes Duplex stainless steel 2507, which is a duplex stainless steel with 4% molybdenum,25% chromium, and 7% nickel. The steel has excellent resistance to chloride stress corrosion cracking, high thermal conductivity and a low coefficient of thermal expansion. Duplex 2507 is designed for applications which require exceptional strength and corrosion resistance; examples include applications in chemical processing, petrochemical, and seawater equipment.

2507(S31750) chemical composition

|

Element |

Content (%) |

|

Chromium, Cr |

24 – 26 |

|

Nickel, Ni |

6 – 8 |

|

Molybdenum, Mo |

3 – 5 |

|

Manganese, Mn |

1.20 max |

|

Silicon, Si |

0.80 max |

|

Copper, Cu |

0.50 max |

|

Nitrogen, N |

0.24 – 0.32 |

|

Phosphorous, P |

0.035 max |

|

Carbon, C |

0.030 max |

|

Sulfur, S |

0.020 max |

|

Iron, Fe |

Balance |

2507(S31750) Physical properties

|

0.2% Proof Stress (N/mm2 ) [ksi] minimum |

550[79.8] |

|

Ultimate Tensile Strength (N/mm2) [ksi] minimum |

800 [116] |

|

Elongation (%) minimum |

25 |

|

Hardness (HBN) |

270 max |

|

Reduction of Cross Section Area (%) |

45 |

|

Charpy V-notch Impact at ambient Temp (J) [ft.lb] |

80min [59min] |

|

Charpy V-notch Impact at -46°C (J) [ft.lb] |

45av, 35min [33av, 25.8min] |

|

Density (Kg.m-1) |

7810 |

|

Magnetic Permeability |

33 |

|

Young’s Modulus (N/mm2) |

199 x 103 |

|

Specific Heat, 20°C (J.Kg-1.°K-1) |

475 |

|

Fracture Toughness, Kq (MPa.m) |

475 |

|

Specific Electrical Resistance, 20°C (µO.m) |

0.80 |

|

Thermal conductivity, 20°C (W.m-1.°K-1) |

14.2 |

|

Mean coefficient of thermal expansion, 20-100°C (°K-1) |

11.1 x 10-6 |

2507(S31750) Application

1-Oil and gas industry equipment

2-Offshore platforms, heat exchangers, process and service water systems, fire-fighting systems, injection and ballast water systems

3-Chemical process industries, heat exchangers, vessels, and piping

4-Desalination plants, high pressure RO-plant and seawater piping

5-Mechanical and structural components, high strength, corrosion-resistant parts

6-Power industry FGD systems, utility and industrial scrubber systems, absorber towers, ducting, and piping

2507(S31750) Welding

2507 possesses good weldability and can be joined to itself or other materials by shielded metal arc welding (SMAW), gas tungsten arc welding (GTAW), plasma arc welding (PAW), flux cored wire (FCW), or submerged arc welding (SAW). 2507/P100 filler metal is suggested when welding 2507 because it will produce the appropriate duplex weld structure. Preheating of 2507 is not necessary except to prevent condensation on cold metal. The interpass weld temperature should not exceed 300°F or the weld integrity can be adversely affected. The root should be shielded with argon or 90% N2/10% H2 purging gas for maximum corrosion resistance. The latter provides better corrosion resistance.

Phone: 0086-18317160019

TEL: 0086-21-61182423

Fax: 0086-21-61182425

E-mail: [email protected]

Skype: shanghai.katalor

Address : Room 301,Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai