- : 0086-21-61182423

- : 0086-21-61182425

- : [email protected]

- : Room 301,Unit 6,lane 2500,xiupu Road,Kangqiao Industrial Area,Pudong New District,Shanghai

- Improper welding of X80 pipeline may cause cracks

- Brief introduction of API X52 pipeline steel

- The difference between PSL1 and PSL2

- Harm of inclusions in X70 pipeline steel

- API 5L pipeline pipe

- X52 steel plate surface quality standards that need to be met

- The basic production process of API 5L X60 pipeline steel

- The key to Q460D steel welding process

- What does the heat treatment of Q690 Steel include?

- Reasons for choosing Q690D steel

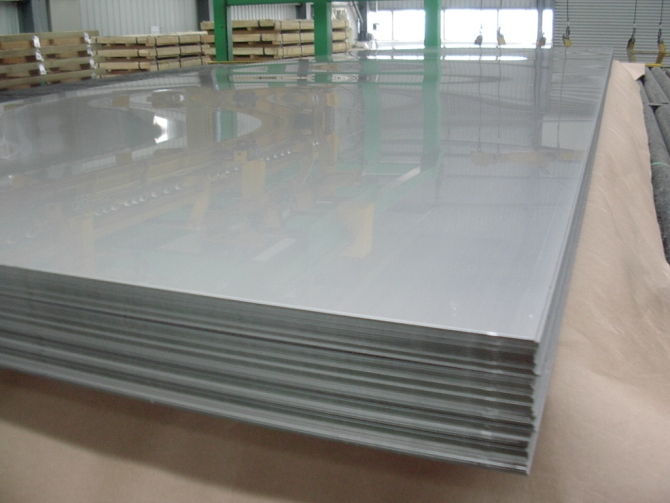

Cold Rolled Steel C1018,Cold Rolled Steel plate

Grade Summary: C1018 is a general purpose low carbon steel with good case hardening qualities. It has a higher manganese content than certain other low carbon grades, such as 1020. Cold Rolled C1018 is better steel for carburized parts, since it produces a harder and more uniform case. Due to size limitations of the cold drawing process, large diameter bars are generally turned and polished. the hot roll rounds usually machine turned, rather than drawn, then abrasively polished. Due to its versatility Cold Rolled C1018 has a larger size selection than other grades.

Typical Applications: Used for parts requiring cold forming, such as crimping, swaging or bending.Also used on carburized parts requiring soft core and high surface hardness such as king pins, gears, dogs, etc.

Available products: Round Bar, Rectangular Bar, Square Bar and Hexagon Bar.

Typical Chemical Analysis: * C – .15/.20 *Mn – .60/.90 *P – .04 Max. *S – .05 Max.

Typical Mechanical Properties**:

Tensile Strength (PSI) 64,000

Yield Point (PSI) 54,000

Elongation*** 15

Brinell Hardness 125

*Chemical Analysis will vary on each heat number

**Properties based on typical 1” bar – All values are minimum values and are representative.

*** % in 2”